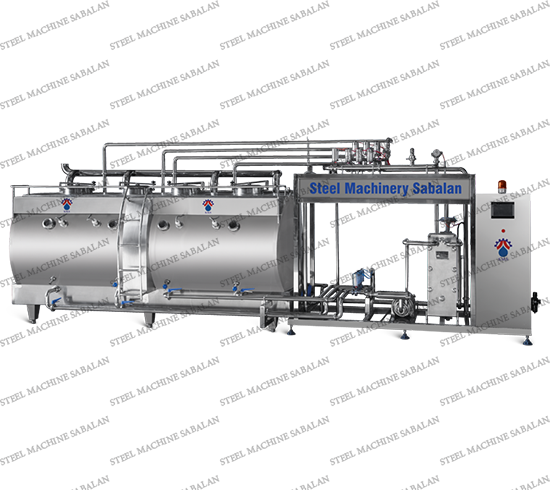

(Central Washer System (Full Automatic CIP

(Central Washer System (Full Automatic CIP

Application: CIP system is the method of cleaning the interior surfaces of pipes, processing equipment, filters and pipe connections and equipment related to the factories, No need for human and hands interference, As well as separating part or parts of the device Indeed, the most important task of the CIP system is in various industries, such as dairy and dairy industries, beverage industries, food and processing industries, pharmaceutical and cosmetics industries that require a high level of health which is a very important advantage. In this way, the operation is very fast and often applicable. All factors and process prerequisites, such as heat treatment, temperature, time, and percentage of detergent, are included. The most important features of the CIP unit are high level of automation, performance change system, optimal energy consumption, high efficiency and adaptation to various food industry lines.

Specifications: This machine consists of four two-wall AISI 316 stainless steel tanks for Caustic, acid, cold water and hot water, thermometer for each tank, ventilator, Check valve, Material entry and exit path, Washing route, dozing equipment and concentration control of detergent solutions, control panel display type PLC alarm lamp, Heater plate, control equipment, Steam supply, manual and automatic valves to control flow, Centrifugal pump, Linear filtering and operator platform installation. All equipment in contact with detergent is stainless steel AISI 316.

Steel machine Sabalan CIP unit is designed and made both semi-automatic and fully automated which used three reservoirs in semi-automatic and another automatic mode that is produced in different capacities and according to customer requirement.